The very first exoskeleton was produced in 1965 for military use. Since that time, exoskeletons have become more and more popular in the manufacturing world, supporting employees and improving the quality of their work.

Exoskeletons are, quite simply, personal assistive technologies that are designed to affect the body mechanically, reducing the load of physical work like heavy lifting, while lessening the risk of musculoskeletal disorders. Ergonomic workplace layout and design are not always possible, for example: temporary workplaces, which is where exoskeletons can help compensate.

But like all new technology, exoskeletons create the need for standards and regulations. Redistributing stress to other parts of the body can impact a workers’ health, comfort and safety. Human-centered equipment design makes exoskeletons useful and accepted in an ever-widening array of industries.

A Growing Trend

In 2018, more than 7,000 exoskeleton units were sold in manufacturing, but the potential market need is much more — at 60,000 units for all types of exoskeletons, backed by an estimated growth rate of more than 50 percent between 2019 and 2024, says Industry Today. This trend will likely grow even beyond that, due to the increasing average age of the population in industrialized countries.

While much of the work in factories has become automated, human input is still critical, and continues to form the foundation of many operations, including repetitive, value-added, precise tasks. When you consider the average worker lifts his or her arm 4,600 times a day, almost a million times a year, to perform tasks, the need for exoskeletons becomes clear.

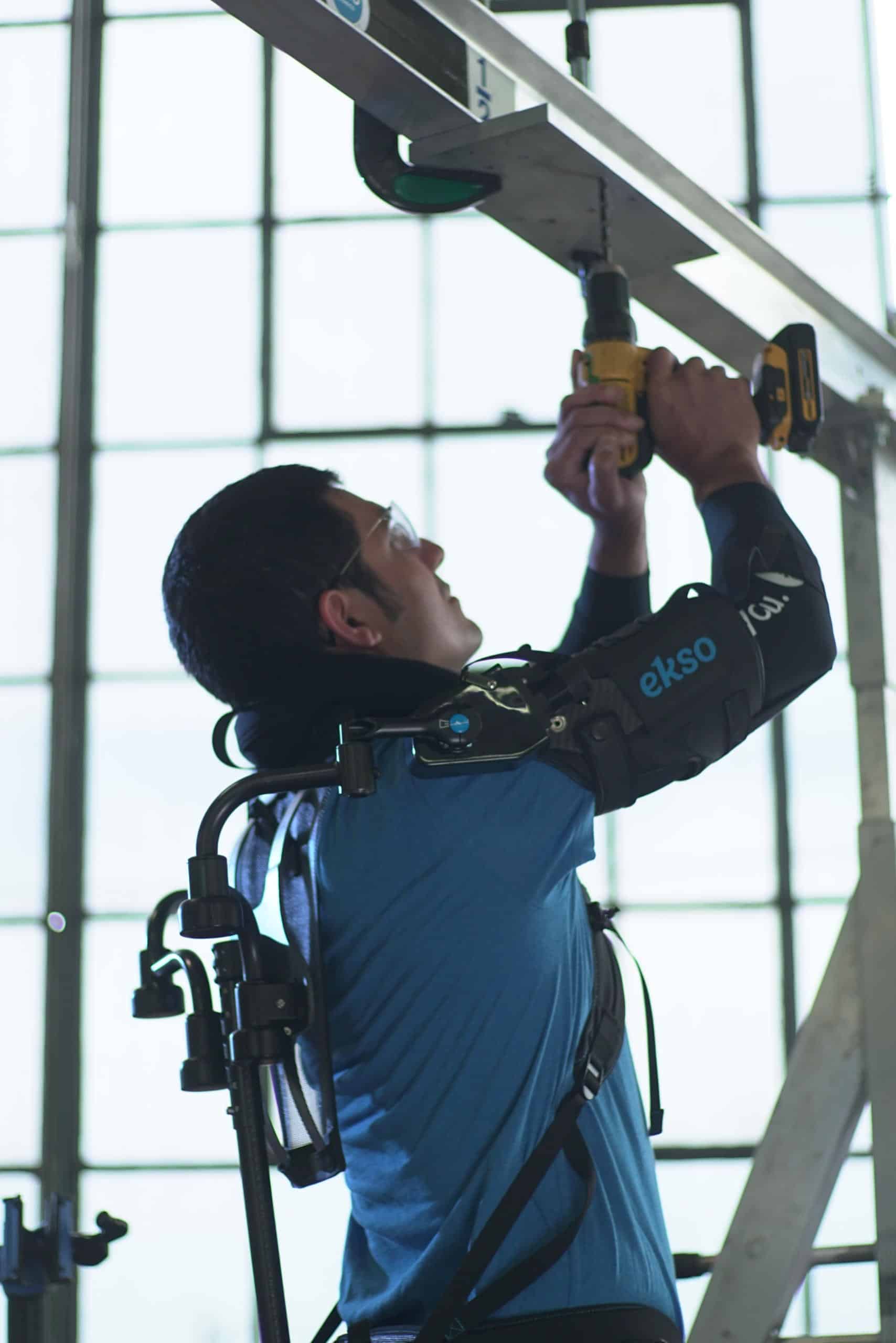

Exoskeletons are essentially wearable robotic technologies that support workers in their jobs, providing postural support that can follow the movements of the arms without misalignment or resistance. This, in turn, can generate a 30 percent reduction in stress on the shoulder muscles. Exoskeletons can support employees in a variety of sectors, including construction, agriculture, services and automotive.

The benefits are many:

- Improved workplace comfort

- Reduced muscle fatigue

- Improved quality of work

- Increased productivity

- Fewer injuries and sick days

Injury Reduction

Let’s take a look at how robotic exoskeletons, AKA exosuits, help construction workers. These light metal and graphite frames basically mimic the human skeleton. When these workers wear exoskeletons, the objects they are lifting seem lighter – in fact, nearly weightless. Exosuits can be passive, with no motors or batteries, or active, which do contain these elements to aid in lifting.

The use of exoskeletons can reduce worker injury. Ford Motor Company, for example, adopted exoskeletons for its workforce in 2011. Since then, they have seen an 83 percent decrease in the amount of injuries reported in units that used the exoskeleton.

Ergonomics experts point out that when injuries occur, they most often impact the shoulder, which consequently suffer the highest number of injuries. On top of that, they take the longest to heal and return to full function. Shoulder surgeries are one of the most expensive orthopedic operations.

Not only do workplace injuries affect the health of employees as well as the company’s bottom line, when fewer workers are injured on the job, there is not as much need for hiring and training people who can replace those who are recuperating.

Best part is, companies can work with manufacturers to design exoskeletons that encompass features addressing their precise needs.

Where Ekso Bionics Fits In

Here at Ekso Bionics, our exoskeletons are designed to solve three main problems in the workplace. It all starts with worker fatigue, and trickles down from there.

- Fatigue

- Injury (caused by fatigue — usually shoulder, sprains, etc.)

- Productivity (hindered by fatigue)

As you can see, fatigue is the main issue here, affecting many other challenges within the workplace. Threatening the output your company can achieve and predicated by frequent injury, fatigue must be addressed first and foremost. That’s where our exoskeletons come in.

Contact Ekso Bionics

To learn more about how exoskeleton suits from Ekso Bionics can impact your workplace for the better, contact us at 510-984-1761 or request a free demo online.