Whether you are lifting heavy objects or completing light and repetitive tasks, construction exoskeletons are your best chance of injury prevention and productivity enhancement. In 2017 alone, there were at least 12,000 injuries per month in the construction industry (1), many of which could have been prevented with the use of exoskeletons. According to research (2), exoskeletons reduce human metabolic cost and thermophysiological response during upper-body work tasks, which translates to less fatigue and strain for workers., resulting in increased productivity. For construction and warehouse workers, exoskeletons are the next industrial shift that will lead to increased efficiency and productivity.

In this article, you will learn what exoskeletons are, how they are applied in construction, and their benefits. Let’s dive in.

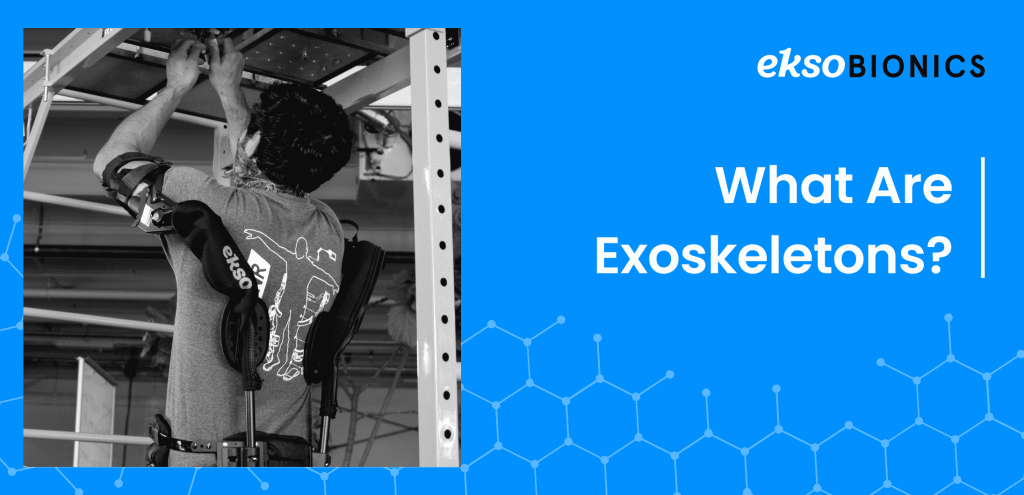

What Are Exoskeletons?

Exoskeletons, also referred to as exosuits, powered-armor, or exo frames, are wearable external frames that offer extra support and enhance a person’s biomechanical capabilities. Think Iron Man from the Avengers, but in real life. The exoskeleton acts as a strength amplifier that augments physical performance or a corrective device for restoring mobility.

Some people believe that exoskeletons are a new “thing”. However, this technology has been in existence since 1890 but has only gained more traction in recent years due to accelerated technology developments. The early model, designed and patented by Nicholas Yagn (3), was a spring-operated device that enhanced the user’s ability to run and jump.

Today, exoskeletons have wide applications and are used in the military, medical, and construction fields. In the medical industry, physical therapists use them as locomotive assistance and gait training devices for patients who have a condition or injury that affects mobility. While in the construction industry, they are primarily used to help workers with their upper extremity mobility by reducing strain and increasing productivity.

There are two types of exoskeletons, powered and passive. A powered exoskeleton contains electric motors, levers, hydraulics, and other technologies that enable limb mobility with increased endurance and strength. It works by sensing the wearer’s motions, sending signals to the motors, and offering the necessary support. A passive exoskeleton differs from a powered exoskeleton because it is purely mechanical. However, they both offer benefits such as shoulder, waist, or thigh support. Additionally, it offers movement assistance when lifting heavy items. Powered exoskeletons are mostly used in military and physical therapy, while passive exoskeletons are more commonly used in construction and other industrial industries.

Exoskeletons and Injury in the Construction Industry

Did you know that the rate of work-related musculoskeletal disorders in construction is 16% higher than in all industries combined?(4) This statistic alone should be enough to point you to the most significant challenge that construction workers face: workplace injury. According to the Construction Chartbook (5), the most common injuries in construction are located in the back, shoulders, and other joints. This can be attributed to the long and repetitive tasks that eventually lead to overexertion and strain to workers’ bodies.

“The most common cause of workplace injuries was overexertion and fatigue. With 20% of construction workers reporting severe pain, construction workers are five times more likely to report poor health. US companies pay nearly $62 billion per year for workplace injuries.” (6)

Workplace injury results in lower productivity, which accumulates to more than 104 million lost production days.(1) In addition, it impacts construction workers’ morale as the uninjured employees have to take up bigger workloads to make up for the injured and recuperating workers. It also affects the injured person’s ability to complete future tasks and lowers their working lifespan.. However, organizations can avoid this by investing in construction exoskeletons.

In a study conducted in 2015 on the application of exoskeletons in industrial applications and their potential effects on physical workload, researchers discovered that exoskeletons greatly reduce fatigue while improving endurance (7). Additionally, exoskeletons reduce shoulder discomfort, thereby improving work quality and productivity among workers. Apart from decreasing the risk of workplace injury, exoskeletons also assist aging workers, and give them an opportunity to work beyond their age and physical limit.

Construction exoskeletons are the future of the construction industry due to the efficiency and productivity opportunities they present. Their primary purpose being: to improve the quality of life for construction workers and prevent injury.

You can use exoskeletons on the manufacturing floor to engage in long-intensive overhead work like installing sensors and filters without straining or injuring yourself. Benefits include joint support that’ll boost your endurance, productivity and prevent injury.

The Construction Exoskeleton Vest

Construction exoskeletons come in different shapes and variations suited to a specific task. Depending on the workload, it can be a full suit, a simple vest to support upper limb mobility or just a glove. Let’s take a look into an exoskeleton vest.

The construction exoskeleton vest is an upper-body exosuit specifically designed to support upper extremity mobility. Its main goal is to reduce workplace injury and worker fatigue by supporting muscle activity and joint movement. It also reduces discomfort when performing repetitive overhead tasks. Let’s establish one important fact; a construction exoskeleton won’t give you ‘Iron Man-level’ superhuman strength. In essence, the vest serves to reduce musculoskeletal loads. You’ll still lift an equal amount of load as you could before. The only difference will be that the load will be lighter and easier to carry since you’ll have additional muscle support.

The construction exoskeleton vest contains features like:

- Lightweight frame: This makes it easy and comfortable to wear.

- Durable materials: The vest is built for the construction environment where they can be exposed to the harshest element and function fully without breakage.

- Assistive: The Exo suit has an adjustable force assistance level that allows you to determine the amount of arm support you want from the suit.

- Natural-tracking: You can wear the suit and move naturally using your intuition, instincts, and reflexes to control it.

- Minimal contact points: This allows workers to work unhindered with a full range of motion and great airflow for comfort.

How Does The Construction Exoskeleton Vest Work?

Exosuits work in different ways depending on how they are powered. Mechanical exoskeletons, which do not use electricity, take weight from certain parts of the body and redistribute it to other areas. For instance, it can take weight from the arms or back when doing tedious overhead work and transfer it to your core to reduce fatigue and strain on muscles and joints. Mechanical exoskeletons are more advantageous since they don’t need to be recharged to use them. So, there’s no downtime. Additionally, they offer more longevity.

On the other hand, electric exoskeletons are more powerful and can handle more weight. They work by increasing pressure and strength in targeted areas as required. The frame responds to the wearer’s motion and provides support when needed. Due to their reliance on power, they can stop work if they run out of charge. In addition, you have to recharge them between uses.

The construction exoskeleton vest is one of the must-have technologies for construction, logistics, and warehouse workers, and for manufacturers who are interested in increasing occupational safety. It is the best solution to reducing muscle pulls, elbow and spinal injuries, and back sprains. It represents the coming together of man and machine to make work easier and more efficient. Let’s dive into the benefits more extensively below.

Fun Fact: The Master Mystery, released in 1919, is the first movie to feature a powered exoskeleton

5 Benefits Of Construction Exoskeletons

You can enjoy many benefits from using industrial exoskeletons, like lifting heavy loads, performing repetitive tasks, reducing the risk of injuries, supporting joints, and increasing work efficiency.

- Injury and Strain Prevention

Exoskeletons cut down on overexertion by supporting workers’ upper limbs when performing monotonous activities. They distribute the user’s weight evenly to the core and waist by reducing strain on the arms and shoulders. This leads to decreased workplace injuries like back sprains and shoulder injuries.

- Withstanding Repetitive Tasks

Picture a construction worker who has to raise their arms over their heads for hours on end plastering a wall or installing drywall. That’s a daunting task, but with a construction exoskeleton, their workload is made more bearable because they have extra support for their arms. They no longer have to go home with joint and back pains, and they can work for more hours without overexerting themselves and thereby increasing their productivity.

- Increased Productivity

Exoskeletons have been proven to increase workers’ endurance by reducing the amount of energy exerted on repetitive tasks. Additionally, since the frame takes on a portion of the musculoskeletal load, it reduces strain on the worker’s muscles and lowers fatigue. Coupled with less injury and strain, this becomes a great productivity enhancer for workers since they can work longer and more efficiently.

- More Work Accuracy

After endless hours of overhead work, accuracy is lowered due to muscle fatigue and exhaustion. However, with an exosuit, you can practically maintain most of your attention and focus on the task at hand without the distraction of strain and fatigue.

- More Opportunities For Aged Contractors

Due to the labor-intensive nature of construction work, older contractors are more likely to be limited by their physical abilities. But with a construction exoskeleton, these workers are able to handle more strenuous work effectively.

Conclusion

In recent years, the construction industry has experienced a lot of automation. However, not every task can be automated and replaced with a robot. There are specific, heavy and repetitive tasks that only humans can do. And the best option for attaining more efficiency and productivity in these non-autonomous tasks is to invest in well-produced exoskeletons. They are an innovative injury prevention solution and present great productivity potential in the construction industry.

If you are considering getting a construction exoskeleton, Ekso Bionics is your best choice. We are the leading company in exoskeleton technologies and have produced some of the best products in the world for the last 17 years. We’ve worked with the United States military, DARPA, Johns Hopkins, Shirley Ryan AbilityLab, Kessler Institute, the Department for Veterans Affairs, and UCLA, among others. Our products are FDA-Approved and are based on clinical experts and feedback from industry leaders.

References:

- https://eksobionics.com/eksoworks/

- The Effects of Upper-Body Exoskeletons on Human Metabolic Cost and Thermal Response during Work Tasks—A Systematic Review https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7600262/

- APPARATUS FOR FACILITATING WALKING, RUNNING, AND JUMPING. No. 420,179 https://patents.google.com/patent/US420179A/en

- Exoskeletons in Construction: Will they reduce or create hazards? https://blogs.cdc.gov/niosh-science-blog/2017/06/15/exoskeletons-in-construction/

- CPWR. The Construction Chartbook. Fifth Ed. CPWR- the Center for Construction Research and Training. Silver Spring, MD. April 2013. http://www.cpwr.com/publications/construction-chart-book

- https://eksobionics.com/construction/

- Exoskeletons for industrial application and their potential effects on physical work load https://pubmed.ncbi.nlm.nih.gov/26444053/